Boeing 737NG MCP Collins Clone

737 autopilot control made & designed by wortelus

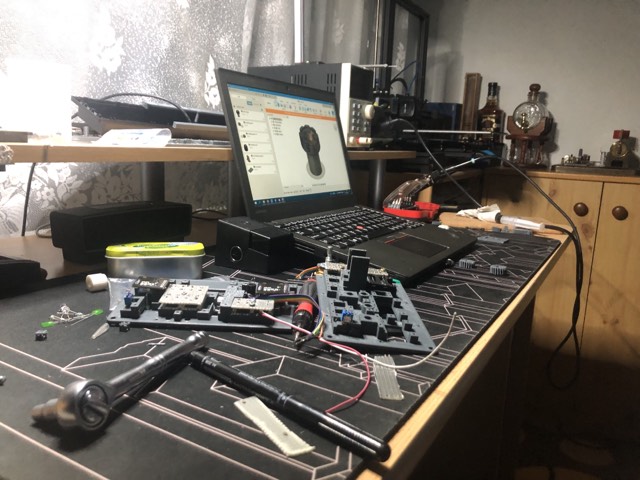

Working prototype, note the actual synchronization with the X-Plane state on the TV.

Intro

This project is a clone of an MCP panel from Boeing 737 Next Generation (especially inspired by the Collins variant). Note that I don't mention replica, we should agree that this is far from the actual real life look. That is due to the fact that I wanted a small portable version to replace the Saitek Multi Panel, so I took Saitek's dimensions and tried to scale down the layout of the real thing.

Despite the fact that this is no fancy replica — it features (I think) nearly every control from the original thing. Even the bank angle selector is present, where most people don't bother to create a double-shaft system for it.

Every part is made using a basic 3D printer - Ender 3 v2, with PETG RAL 7011 filament.

Output Interfaces (displays, indicators)

First of all, we start by getting the components to try and fit on the back plate. What was kinda lucky is the fact that all of the naked mounts of 7-segment displays were able to fit next to each other on the backside. The first problem was the need to remove their respective TM1637 integrated circuit boards, which were too wide to fit next to each other on the back side. This made the necessity to actually mount the IC's 7seg displays. Not a complex problem, but a lot of crimping, wiring and soldering.

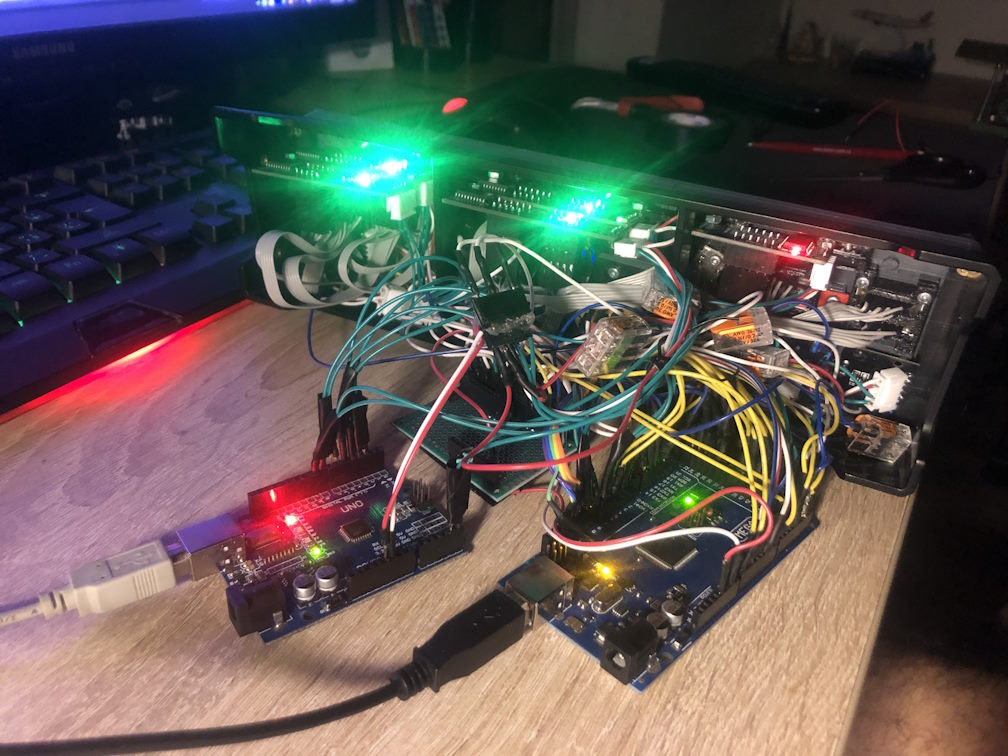

As per the output peripherals, this project consists of those following components:

- 14 status mode indicators on buttons

- 3 signaling panel mounted LED's

- 5 controlling TM1637 chip boards

- 6 separate 7 segment displays

The next challenge was the need to actually use different software to operate TM1637 chips. MobiFlight does not support them and is not even planning to do so. I ended up writing my own atmega328p software for a second arduino, which supplies the serial communication with the TM1637 chips. I might change to a different driver software, but for now it's enough.

Input peripherals

As far as I know, every peripheral that is on the real thing should be included. All 14 buttons, A/T switch, F/D switches, A/P disengage switches, rotary encoders for every MCP display. I did not even forget the most overlooked one, the bank angle selector. Most even hobby built real replicas lack this feature. Bank angle selector installation is however different to other encoders, which can be mounted simply directly from the back, as you need two shafts - one to control the heading (the inner shaft), and the other one to actually control the bank angle (the outer shaft).

The LED indicators were solved by simple diffusion LEDs with dimensions of 2x5x7mm. They have proven to be a suitable choice and are closely fitted in their holes among with some hot glue directly on the buttons. This is probably the only limitation in terms of disassembly, as their removal requires some heating, which can damage the text and engravings if used irresponsibly (for too long or too hot).

Speaking of the engravings, this is quite an interesting part. The buttons needed to be printed with at least 0.3mm nozzle to achieve the detail in the small text. 0.3mm nozzle size is quite enough. The technique used to make this is the real fun here. We can fill the text using a VERY fine needle and a syringe. The paint used to do that is an idea I came across thanks to this YouTube video:

Nail polish diluted with the help of acetone has proven to be a very good technique if you practice a little bit with such small letters like the ones on the 10x10mm buttons.

However, I had to limit myself up to 3 letters due to the size of the buttons.

Finally, the buttons are mounted on simple microswitches with elevated head. I'd like to

point out that you need to have calibrated tolerance on your 3D printer for the buttons to fit just right.

Gallery